Introduction

In the ever-evolving landscape of electronics manufacturing, Surface Mount Technology (SMT) stands as a cornerstone, propelling innovations and efficiencies. With the rapid pace of technological advancement, manufacturers require solutions that are not only fast but also precise and reliable. Enter Faroad, a leader in intelligent equipment manufacturing, whose high-speed pick and place machines are setting new standards in the SMT industry. In this article, we explore how Faroad is revolutionizing electronics manufacturing and what the future holds for SMT.

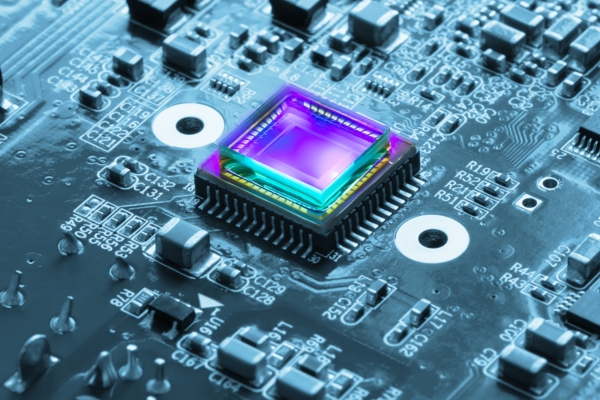

The Evolution of Surface Mount Technology (SMT)

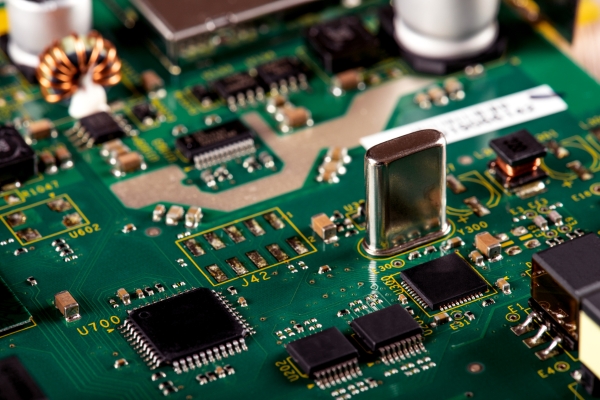

Since its inception, SMT has transformed the way electronic components are assembled, offering compact, efficient, and robust solutions. Traditional through-hole technology has been largely replaced, allowing for denser, more reliable circuit boards. However, as the demand for sophisticated electronic devices grows, so does the need for more advanced SMT solutions.

Faroad’s Commitment to Innovation

At the heart of Faroad’s success lies a relentless commitment to innovation. Founded in 2006, Faroad has grown into a national high-tech enterprise with numerous patents and a substantial footprint in the global market. By integrating cutting-edge technology with customer-centric design, Faroad has pioneered advancements in high-speed pick and place machines, making them a preferred choice for leading electronics manufacturers like Huawei, Samsung, and Lenovo.

Key Features of Faroad’s High-Speed Pick and Place Machines

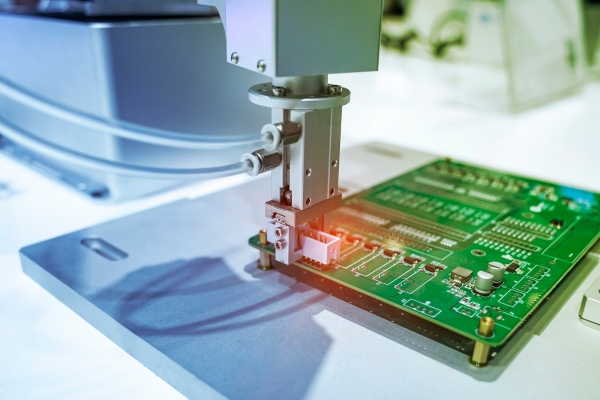

Unmatched Speed and Precision

Faroad’s pick and place machines, such as the CPM-H3, CPM-H5, and CPM-S5, are engineered for speed and precision. With capabilities reaching up to 84,000 components per hour (CPH), these machines ensure rapid production cycles without compromising accuracy. The dual-arm configurations and high-precision control systems guarantee consistent performance, crucial for high-volume manufacturing.

Advanced Integration and Customization

Supporting full MES (Manufacturing Execution System) integration, Faroad’s machines offer smart factory management, allowing seamless connectivity and control. The modular design and customization capabilities ensure that manufacturers can tailor their equipment to specific production needs, whether it’s for consumer electronics, automotive components, or telecommunications devices.

Robust Build and Reliability

Faroad’s commitment to quality extends to the materials and processes used in manufacturing their machines. Each unit undergoes rigorous testing, using high-precision equipment to ensure that every component meets the highest standards. This dedication to quality results in machines that are not only reliable but also durable, minimizing downtime and maintenance costs.

Applications in Modern Electronics Manufacturing

Faroad’s high-speed pick and place machines are versatile, finding applications across a wide range of industries:

- Consumer Electronics: From smartphones to laptops, Faroad’s machines handle the mass production of complex electronic assemblies with ease.

- Automotive Industry: As vehicles become increasingly reliant on electronic systems, precision and reliability are paramount. Faroad’s solutions ensure seamless integration of automotive electronics.

- LED Manufacturing: The machines are ideally suited for the large-scale production of LED panels, lighting, and backlighting modules.

- Telecommunications: High-frequency telecommunication devices demand accuracy, which Faroad’s pick and place machines consistently deliver.

The Competitive Edge of Faroad’s Solutions

What sets Faroad apart in the competitive landscape of SMT equipment manufacturers? It boils down to a combination of technology, expertise, and strategic market positioning.

Unified Equipment Management

Faroad offers a unique advantage with its unified equipment management platform. This system allows manufacturers to oversee production lines with a single standard, reducing complexity and enhancing operational efficiencies. The platform supports a range of PCB sizes and complex products, providing a one-stop solution for diverse manufacturing needs.

Cost-Effectiveness

Compared to imported brands, Faroad provides a cost-effective alternative without sacrificing quality. The ability to source from a single supplier minimizes the risk and cost associated with dealing with multiple vendors, ensuring a streamlined procurement process.

Customization and Support

Faroad’s ability to customize equipment to specific customer requirements ensures that each solution is tailored to maximize productivity and efficiency. Additionally, Faroad’s global sales and after-service channels provide comprehensive support, ensuring that customers receive assistance whenever they need it.

Customer Success Stories

Faroad’s machines have transformed the operations of numerous global enterprises. For instance, a leading consumer electronics manufacturer achieved a 30% increase in production efficiency by integrating Faroad’s high-speed pick and place machines into their assembly line. Similarly, an automotive parts supplier reported significant reductions in defect rates, thanks to the precision and reliability of Faroad’s solutions. These success stories are a testament to Faroad’s impact on the industry.

Conclusion

As the demand for electronic devices continues to grow, the need for efficient, reliable, and advanced manufacturing solutions becomes ever more critical. Faroad’s high-speed pick and place machines are at the forefront of this evolution, offering unparalleled speed, precision, and integration capabilities.

If you’re ready to elevate your manufacturing capabilities and stay ahead of the competition, it’s time to partner with Faroad. Explore our range of high-speed pick and place machines and discover how we can help you achieve your production goals. Contact us more information to discuss your specific needs and find the perfect solution for your business. Together, let’s revolutionize the future of SMT manufacturing.