Odd Shape Pick and Place Machine

Precision and Versatility for Unique Component Challenges

High-Precision Complex Placement

Our Odd Shape Pick and Place Machines utilize built-in vacuum pumps and magnetic levitation motion control to adapt to all kinds of odd-shaped components. Whether you are dealing with small, intricate parts or larger, more complex components, our machines ensure precise placement at speeds up to 8000 CPH, maintaining consistent quality and performance.

Intelligent Software and MES Integration

Equipped with self-developed software, our machines are perfectly suited for both domestic and international markets. The user-friendly interface supports offline programming and integrates seamlessly with MES systems, allowing real-time tracking of equipment production and quality management. This ensures that your production lines are always running at optimal efficiency.

Universal Compatibility

Faroad’s Odd Shape Pick and Place Machines offer universal compatibility with a variety of feeders, ensuring you can handle any production need. The high-speed, multifunction placement heads can be configured to accommodate diverse component types, making these machines the ideal solution for industries requiring flexibility and precision.

Use Cases and Applications:

- Automotive Electronics: Specifically designed for assembling odd-shaped components used in automotive electronics such as sensors and control units.

- Smartphone Manufacturing: Ideal for placing non-standard components in smartphones that require special handling.

- IoT Devices: Suitable for assembling IoT devices that often involve irregularly shaped components.

- Aerospace Electronics: Useful in the aerospace sector for assembling complex electronic systems with non-standard parts.

- Medical Devices: Applicable in the production of medical devices that utilize custom-shaped electronic components.

Odd Shape – Pick And Place Machines

Specs Overview

Flexibility

High-speed / Multi-function Placement heads are configured according to customer component types.

Universal Compatibility With Diverse Feeders

Universal compatibility with a variety of feeders such as 60mm and 100mm, which are suitable for various production needs.

Suitable For Odd Shape Components

Suitable for labels, adhesives, foam, conductive adhesive/cloth, Mylar, copper foil, thermally conductive silicone, graphite sheet, 3D steel sheet, headphone components, mobile phone case materials, glass panel texture film, battery cover, 3C products and Accessories.

Independent Z Axis Control

By the simple creation of the component shape and automatic preservation of the recognition data, the machine can recognize complex components rapidly.

High Precision Reliability

Imported XY drive and magnetic levitation linear motor with grating ruler.

High-precision Scanning Camera

Imported linear scanning cameras can meet the inspection requirements of high-resolution components and realize the various complex components simultaneously.

Thermal Compensation Calibration

Monitor and automatically correct the placement accuracy in real time to ensure the stability of the high-speed operation of the equipment.

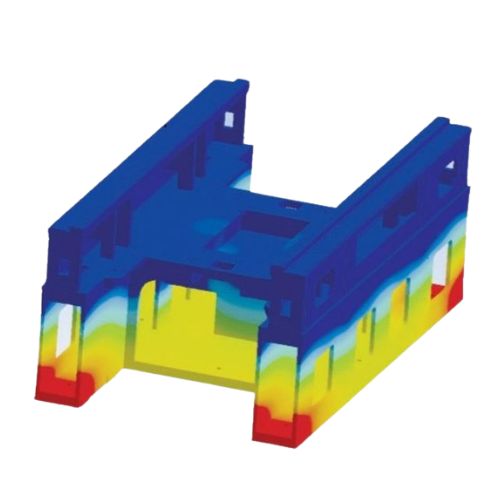

One-piece Molding Rack

A cast one-piece frame undergoes 365 days of natural aging to relieve stress and adopts a high-temperature annealing process to prevent thermal deformity and thermal deformation of high-speed movement.

Intelligent Software System

Non-standard Components Can Be Edited

Newly developed intelligent digital alignment algorithm used to realize non-standard components/irregular-shaped irregular components by the function of one-click editing.

Path Optimization

To achieve the best equipment utilization rate, the Intelligent algorithms such as ant colony algorithm/cluster analysis/AI deep learning are newly added to realize the optimal optimization path for both picking and placement.

Coordinate Import

One-click import of coordinates data through text files such as text format, EXCEL files, etc.

Support Mes System Collection

MES system can realize intelligent management of equipment production, quality, efficiency, etc. Improve manufacturing efficiency.

Lan Management

Local area network management, software database and online machine database online communication update, realizing local area network network database to prevent virus transmission.

Support Mes Upload

Automatic identification of QR code or bar-code after placement done, then uploads the data to MES server to achieve traceability.

A GUIDE TO

How to choose the perfect pick and place machine for your smt line in 2024?

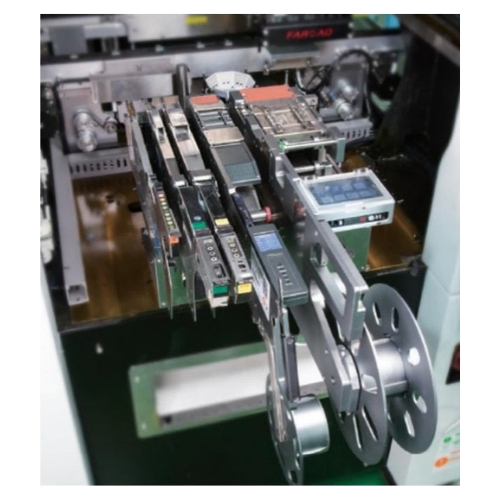

CPM-FB – Odd Shape Pick And Place Machine

Introducing the CPM-FB, Faroad’s high-end odd shape pick-and-place machine. Designed for exceptional flexibility and precision, the CPM-FB can handle diverse and complex components with a placement speed of up to 8,000 CPH, making it an ideal solution for advanced SMT production lines.

Functions & Features

Enhanced Performance

The CPM-FB features a built-in vacuum pump adaptable to various odd-shaped components. Its high-speed eight heads and multi-functional four heads enable simultaneous production of different component types. Magnetic levitation motion control ensures high-speed precision and reliabilit

Intelligent Software System

Equipped with user-friendly software, the CPM-FB supports both Chinese and International markets. Its touch screen operation, offline programming, and MES integration allow for efficient production tracking and quality management.

Flexible Component Handling

Designed for versatility, the CPM-FB accommodates high-speed and multi-functional placement heads, compatible with diverse feeders like 60mm and 100mm. It handles a wide range of odd-shaped components, from labels and adhesives to thermally conductive silicone and more.

Detailed Specification

| Model | Category | CPM-FB |

| Size | L*W*H | 900*1420*1550mm |

| gross weight | 1000KG | |

| Min and Max PCB size | Min50*50mm,max330*420mm (option 450*500mm) | |

| PCB thickness | 0.5MM-5mm | |

| PCB Fixture method | Upper and lower splint | |

| Operating System | Windows system | Windows7/10 |

| Control System | Self Developed Software | |

| Display input device | Touch screen + keyboard, mouse | |

| Placement | Mounting speed | 3000CPH-8000CPH |

| Number of placement heads | 4/8 heads | |

| Mounting accuracy | +0.035mm(excluding material tolerance) | |

| Mounting height | 0.1-8MM (automatic conversion, 30mm optional) | |

| Mounting angle | 0-360degrees | |

| Size of mountable Components | Standard rnodels are applicable:1.5*2r-90*38mm | |

| Applicable to enlarged models:10mm*5mm-180mm*38mm | ||

| Almost all cold paste products can be attached, including adhesive tape film, special-shaped | ||

| reinforcement, 3D steel sheet, label, foam, glass and special-shaped components, etc. | ||

| Visual System | Camera ldentificaton | Linear scan camera & area scan camera |

| Transmission System | Transmission direction | left-right, right-left, left-left, right-riaht |

| delivery method | automatic | |

| Converyor height | 900±20mm | |

| Electrical Specifcations | air pressure | 5.0KG comes with vacuum pump |

| input power | AC 380/420/480V 50hz | |

| power | 1.5KW | |

| Use environment | 24.5°C± 2°C | |

| Feeding System | Number of feeders that can be placed | 2 feeder for 100mm wide 4 feeder for 60mm wide SMT standard feeder can be 21 stations |

Get in Touch.

Office

Building 3, Phase II, No. 9 Furong Road, Songgang Street, Baoan District, Shenzhen.

Contact

Open Hours

Monday & Saturday: 9 am — 7 pm

Saturday: 8 am — 12 pm