- Introduction

- The Growing Demand for LED Manufacturing

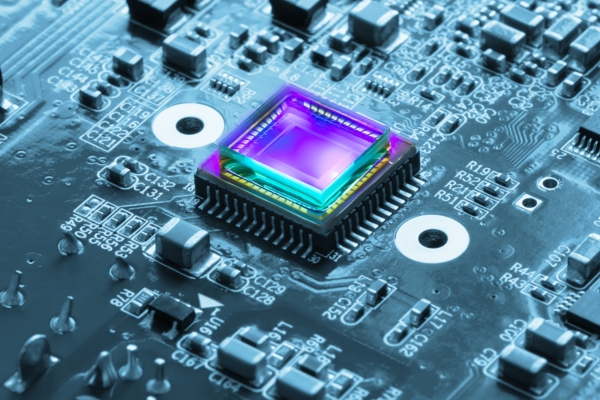

- Challenges in LED Production

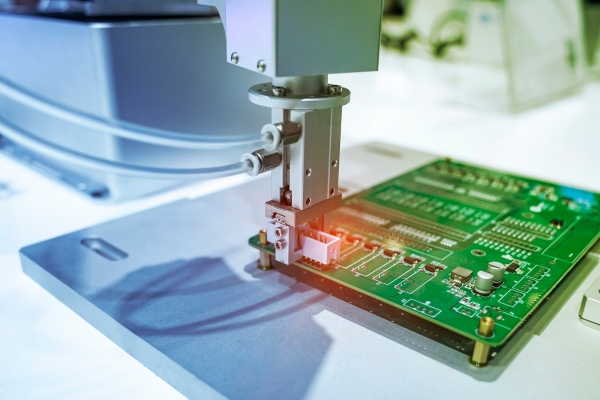

- Faroad’s Specialized Pick and Place Machines: A Comprehensive Overview

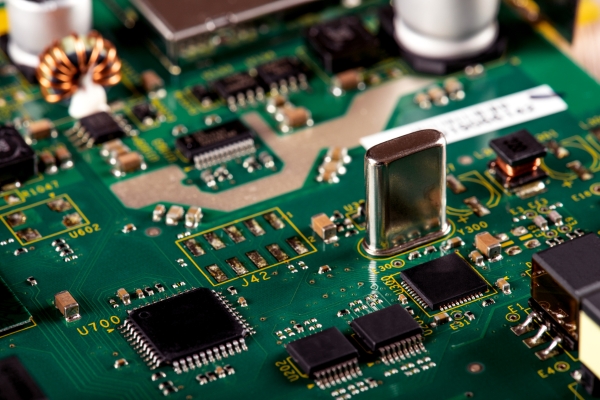

- Key Features Enhancing LED Manufacturing Efficiency

- Real-World Applications and Success Stories

- The Competitive Advantage of Faroad’s Machines

- Conclusion

Introduction

In recent years, LEDs have become ubiquitous, lighting up our homes, streets, and devices. As the demand for LEDs continues to soar, manufacturers face the challenge of increasing production efficiency while maintaining quality. Faroad, a leader in intelligent equipment manufacturing, offers specialized pick and place machines designed to transform LED manufacturing processes. In this article, we explore how Faroad’s innovative solutions maximize efficiency in LED production and why they’re a game-changer for manufacturers worldwide.

The Growing Demand for LED Manufacturing

The shift towards energy-efficient, sustainable lighting solutions has propelled the LED market to unprecedented heights. From residential and commercial lighting to automotive and consumer electronics, LEDs are the preferred choice for a wide array of applications. As a result, manufacturers are under pressure to scale up production while ensuring precision and cost-effectiveness.

Challenges in LED Production

LED manufacturing presents unique challenges that require specialized solutions:

- Precision and Accuracy: LEDs are small and delicate, necessitating precise placement to ensure optimal performance.

- High-Volume Production: With growing demand, manufacturers need machines capable of handling high-volume production without compromising quality.

- Complex Assembly: The assembly of LED modules often involves multiple components and intricate designs, requiring machines with versatility and adaptability.

Faroad’s Specialized Pick and Place Machines: A Comprehensive Overview

Recognizing these challenges, Faroad has developed a range of specialized pick and place machines tailored specifically for LED manufacturing. These machines, including models like the CPM-L2 and L3-600, are engineered to meet the demands of modern LED production with unmatched speed, precision, and reliability.

Model Highlights

- CPM-L2 / L1200: Capable of achieving up to 70,000 CPH, this model is designed for high-speed LED lamp bead and component placement, with support for large PCBs up to 1200x400mm.

- L3-600 / L3-1200: Offering speeds of up to 80,000 CPH, this machine integrates advanced XY drive linear motors for enhanced accuracy and stability, ideal for complex LED assemblies.

Key Features Enhancing LED Manufacturing Efficiency

Faroad’s specialized pick and place machines incorporate a host of features that directly contribute to maximizing efficiency in LED production:

High-Speed Placement Heads

With placement speeds reaching up to 80,000 CPH, Faroad’s machines ensure rapid throughput, reducing production cycle times and increasing overall efficiency.

Advanced Drive Systems

The use of dual linear motors for XY drive and one-piece molding bases enhances precision and stability, crucial for the intricate placement of LED components.

Intelligent Software Integration

Faroad’s machines are equipped with intelligent software systems that facilitate component editing, path optimization, and MES integration. This allows manufacturers to streamline operations and maintain production quality.

Compact and User-Friendly Design

Designed with space efficiency in mind, these machines are compact and easy to operate, making them ideal for factories with limited space. The user-friendly interface ensures smooth operation, minimizing the learning curve for operators.

Real-World Applications and Success Stories

Faroad’s specialized pick and place machines have been instrumental in transforming LED manufacturing processes for companies around the globe. For example, a leading lighting manufacturer reported a 40% increase in production efficiency after integrating Faroad’s machines into their assembly line. Similarly, an electronics giant achieved significant cost savings by optimizing their LED backlight production with Faroad’s solutions.

These success stories underscore the tangible benefits of adopting Faroad’s technology in LED manufacturing, highlighting improved efficiency, reduced waste, and enhanced product quality.

The Competitive Advantage of Faroad’s Machines

Faroad stands out in the market due to its commitment to innovation and customer satisfaction. Here are some reasons why Faroad’s machines offer a competitive edge:

Cost-Effective Solutions

By providing a single supplier for comprehensive SMT solutions, Faroad reduces the complexity and cost associated with sourcing from multiple vendors. This cost-effectiveness is a major advantage for manufacturers looking to optimize their operations.

Customization and Scalability

Faroad’s machines are designed with customization in mind, allowing manufacturers to tailor equipment to their specific production needs. This flexibility ensures scalability, enabling businesses to grow and adapt to market demands.

Global Support Network

With sales and after-service channels across Southeast Asia, the Middle East, South America, and Europe, Faroad offers robust support to its customers, ensuring they have the assistance they need to succeed.

Conclusion

In the fast-paced world of LED manufacturing, efficiency and precision are paramount. Faroad’s specialized pick and place machines offer the perfect solution, designed to meet the unique challenges of LED production. With advanced features, intelligent integration, and a commitment to quality, Faroad is your partner in achieving manufacturing excellence.

If you’re ready to revolutionize your LED manufacturing processes and gain a competitive edge, explore Faroad’s range of specialized pick and place machines today or contact our expert team to discuss how we can tailor our solutions to meet your specific needs. Let’s illuminate the future of LED manufacturing together.