High-Speed LED Pick and Place Machines

Precision, Efficiency, and Reliability in One Compact Solution

Unmatched Performance for LED Manufacturing

Our high-speed LED pick and place machines are designed to meet the demanding needs of modern LED manufacturing. With production capacities of up to 80,000 CPH, these machines offer unparalleled efficiency and precision. The advanced XY drive linear motors ensure higher accuracy and stability, making them the perfect choice for high-volume production lines.

Innovative Features for Optimal Efficiency

Equipped with state-of-the-art features such as area scan cameras for simultaneous identification of multiple components and automatic calibration systems with thermal compensation, our machines ensure maximum production capacity and minimal downtime. The multifunctional placement heads and lightweight electric feeders further enhance productivity, allowing for seamless and efficient operations.

Compact and User-Friendly Design

Our LED pick and place machines are designed with a small footprint, making them ideal for factories with limited space. The moveable PCB transmission system reduces board transfer waiting times, while the high-precision thermal compensation calibration device ensures consistent accuracy. With user-friendly interfaces and easy maintenance, these machines provide a hassle-free experience, enabling you to focus on what matters most—producing high-quality LED products.

Use Cases and Applications:

- LED Lighting Production: Specifically designed for assembling LED lighting products, ensuring high-speed and accurate placement of LED components.

- Signage and Display Boards: Ideal for the production of LED signage and display boards, which require precise and efficient assembly.

- Automotive LED Lights: Suitable for assembling LED lights used in automotive applications, ensuring durability and performance.

- Consumer Electronics: Can be used for LED backlighting in consumer electronics such as TV screens and monitors.

- Architectural Lighting: Useful in the production of LED modules for architectural lighting solutions.

LED Model – Pick And Place Machines

Specs Overview

Model Navigation

Configurations that Define Excellence

Feature Details

LED Pick And Place Machine Is Suitable For High Speed Production Requirement

High-efficiency Configuration Of Equipment To Maximize Production Capacity

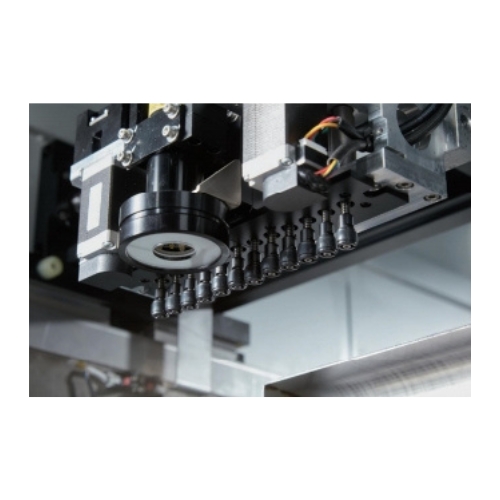

High-speed Placement Head

12 placement heads work simultaneously to increase the production capacity by nearly 30% compared with the traditional configuration, and can achieve the best production capacity of 70,000 CPH.

Moveable PCB Transmission

Movable PCB transmission system reduces the waiting time for board transfer and optimizes the placement path.

Electric Feeder

The electric feeder can realize 1/2/4mm pitch feeding to save equipment cost and improve component compatibility.

Other Features

Panasonic Servo Drive

Imported lead screw and Panasonic servo.

Mark Camera

It can automatically scan the placement coordinates to improve efficiency.

High-precision Thermal Compensation Calibration Device

High-precision thermal compensation correction device can monitor and automatically correct the placement accuracy in real time.

A GUIDE TO

How to choose the perfect pick and place machine for your smt line in 2024?

Explore Models

L3-600 / L3-1200 – LED Model Pick And Place Machine

The L3-600/L3-1200 is Faroad’s latest high-speed LED placement machine, designed to deliver unmatched precision and efficiency. As a leader in smart SMT technology, Faroad ensures this machine offers top-tier performance with a production capacity of up to 80,000 CPH

Functions & Features

Precision XY Drive System

Featuring dual linear motors, the L3-600/L3-1200 provides higher precision and stability with minimal wear. Its one-piece molding base enhances mounting stability, ensuring consistent and accurate component placement.

Advanced Camera and Calibration

The area scan camera allows simultaneous identification of multiple components, optimizing placement. The automatic calibration system with thermal compensation ensures real-time accuracy, while the built-in suction nozzle buffer protects components from damage.

Efficient Performance

With a multifunctional placement head, the L3-600/L3-1200 boosts production capacity by nearly 30%, achieving up to 18,000 CPH. Its lightweight electric feeder supports 2/4mm pitch feeding, reducing costs and improving compatibility. The movable PCB transmission system minimizes waiting time, optimizing the mounting process.

Detailed Specification

| Model | Category | CPM-L3-600 | CPM-L3-1200 |

| Name | Equipment Name | Lamp beads special placement machine | |

| Placement head | Mounting head model | 1212B | |

| Nozzle spacing | 12mm | ||

| Number of nozzles | High-speed placement head (12 heads) | ||

| Equipment size | Length x width x height | 1140*1500*1450mm | |

| The main components | Base | High-strength cast iron one-piece molding | |

| X-arm beam | High-strength aluminum stretch forming | ||

| Control section | X-axis | Flat linear motor + grating ruler | |

| Y-axis | Dual motor linear motor + grating ruler | ||

| Z-axis | Closed loop stepping | ||

| R-axis | Closed loop stepping | ||

| Mounting capability | Optimal placement speed (IPC-9850) | 70000CPH | |

| Chip placement accuracy (CPK) | 0,10mm(XYZ), CPK ≥ 1.0 | ||

| Component size | Minimum size: 0201, maximum size: L12*W12 | ||

| Component thickness | 18mm | 18mm | |

| Weight | weight | About 1600KG | About 1680KG |

| Electrical Specifications | Gas source | 0.5MPa,150L/min | |

| Power supply / Power | AC380/420/480V, 2.5KW | ||

| PCB conveyor system | Transfer plate track | Mobile single-section track (with transfer function) | |

| PCB size | Minimum 50*50mm, Maximum 600*400mm, Maximum 1200*400mm | ||

| PCB Thickness | 0.4-9.5mm | ||

| PCB fixing method | Pneumatic lifting platform, upper and lower clamps | ||

| Feeding system | Number of feeders | 37 stations (8mm) | |

| MES system connection | MES Collection | Support TCP/IP communication protocol | |

| MES Upload | Support QR code / barcode recognition / binding upload MES | ||

| Optional accessories | Optional accessories | Offline loader / rear button panel |

CPM-L3T – LED Model Pick And Place Machine

The CPM-L3T is Faroad’s innovative lens mounting machine, designed for high-speed and high-precision applications in TV backlights, LED lighting, and more. As a leader in high-end smart SMT machines, Faroad ensures exceptional performance and increased production capacity by nearly 50%.

Functions & Features

High Speed and Precision

The CPM-L3T integrates a high-speed placement head with an advanced XY linear motor drive system, ensuring rapid response and high-precision closed-loop control. The one-piece molding frame, aged for 365 days and treated with high-temperature annealing, guarantees stability and prevents deformation, even during high-speed operations.

Advanced Recognition and Calibration

Equipped with a flying camera recognition system, the CPM-L3T reduces recognition time, enhancing efficiency. The high-precision thermal compensation calibration device continuously monitors and corrects placement accuracy in real time, while 8 independent cameras boost production efficiency by identifying materials simultaneously.

Intelligent Software and Management

The CPM-L3T’s intelligent software system includes a digital centering algorithm for easy editing of non-standard devices. It supports one-click import of mounting coordinates and LAN management for seamless database updates. The integrated MES management system enhances manufacturing execution by enabling intelligent production, quality, and efficiency management.

Detailed Specification

| Model | Category | CPM-L3T |

| Name | Equipment Chinese name | Lens mounter |

| Mounting head model | 0821BL | |

| Nozzle spacing | 21mm | |

| Number of nozzles | Multifunctional placement head (8 heads) | |

| Equipment size | Length x Width x Height | 1140*1500*1450mm |

| The main components | Base | High-strength cast iron one-piece molding |

| X-arm beam | High-strength aluminum stretch forming | |

| Control section | X-axis | Flat linear motor + grating ruler |

| Y-axis | Dual motor linear motor + grating ruler | |

| Z-axis | Closed loop stepping | |

| R-axis | Closed loop stepping | |

| Mounting capability | Optimal placement speed (IPC-9850) | 28000CPH |

| Chip placement accuracy (CPK) | 士 0,10mm(XYZ),CPK ≥ 1.0 | |

| Component size | Minimum size: 0201, maximum size: L20*W20″ | |

| Component thickness | 24mm | |

| Weight | weight | About 1600KG |

| Electrical Specifications | Gas source | 0.5MPa,150L/min |

| Power supply / Power | AC380/420/480V,2.5KW | |

| PCB conveyor system | Transfer plate track | Fixed three-section track (with standby function) |

| PCB size | Minimum 50*50mm, maximum 600*400mm (single-stage mounting), maximum 1200*400mm (two-stage mounting) | |

| PCB Thickness | 0.4-9.5mm | |

| PCB fixing method | Pneumatic lifting platform, upper and lower clamps | |

| Feeding system | Number of feeders | 20 stations (8mm) |

| MES system connection | MES Collection | Support TCP/IP communication protocol |

| MES Upload | Support QR code / barcode recognition / binding upload MES | |

| Optional accessories | Optional accessories | 16-position nozzle changer, fixed rear tray, portable front tray, offline loading cart, rear button panel |

Get in Touch.

Office

Building 3, Phase II, No. 9 Furong Road, Songgang Street, Baoan District, Shenzhen.

Contact

Open Hours

Monday & Saturday: 9 am — 7 pm

Saturday: 8 am — 12 pm