Introduction

In the ever-evolving landscape of electronics manufacturing, the demand for unique, non-standard components continues to rise. From automotive electronics to IoT devices, manufacturers are faced with the challenge of assembling intricate and irregularly shaped parts. Faroad, a pioneer in intelligent equipment manufacturing, offers a solution with its specialized odd shape pick and place machines. This article explores how Faroad’s technology addresses the complexities of modern manufacturing, ensuring precision, efficiency, and adaptability in handling unique component challenges.

The Rise of Complex Component Manufacturing

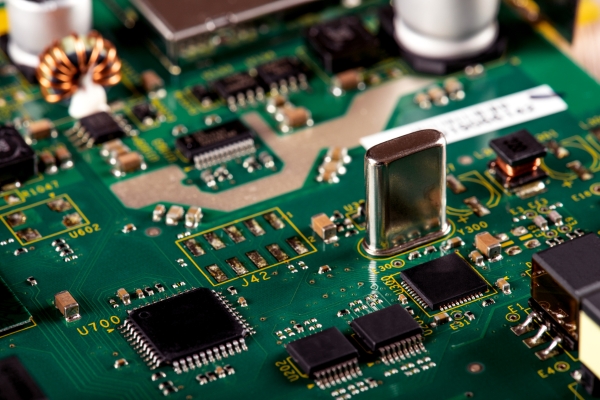

As technology advances, the need for specialized components has grown across various industries. Automotive systems require sensors and control units with unique shapes, while IoT devices often incorporate non-standard parts to enhance functionality. This trend towards complexity necessitates innovative solutions that can seamlessly integrate these components into production processes.

Challenges in Handling Odd-Shaped Components

Manufacturers face several challenges when dealing with odd-shaped components:

- Precision Placement: Irregular shapes require precise handling to prevent misalignment and ensure optimal performance.

- Versatility in Handling: With a wide range of component sizes and shapes, machines must be adaptable and flexible.

- High-Volume Production: Meeting production demands while maintaining quality is crucial, especially as the complexity of components increases.

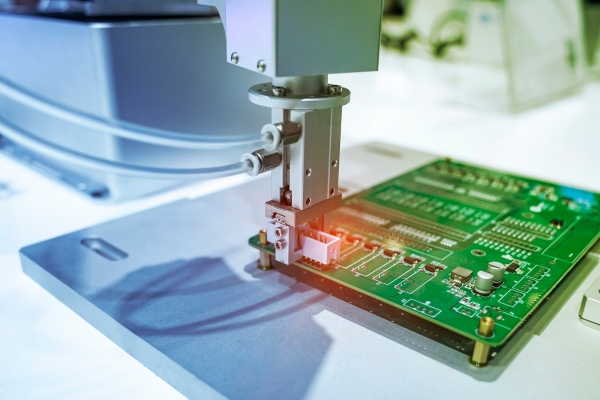

Faroad’s Odd Shape Pick and Place Machines: A Detailed Overview

Faroad’s odd shape pick and place machines are engineered to conquer the challenges posed by unique components. Models such as the CPM-FB offer unparalleled versatility and precision, making them ideal for industries with demanding assembly requirements.

Model Highlights

- CPM-FB: This high-end machine is designed for exceptional flexibility, capable of handling diverse and complex components at speeds up to 8,000 CPH. It features built-in vacuum pumps and magnetic levitation motion control to adapt to various odd-shaped components.

Key Features and Technologies

Faroad’s odd shape pick and place machines incorporate advanced technologies that enhance their performance and reliability:

Flexible High-Speed/Multi-Function Placement Heads

The ability to configure high-speed and multi-function placement heads allows manufacturers to handle a wide array of components with ease, ensuring efficient production without compromising quality.

Magnetic Levitation Motion Control

This innovative technology provides high-speed precision and reliability, crucial for the accurate placement of irregularly shaped components. The magnetic levitation system reduces friction, ensuring smooth and stable operation.

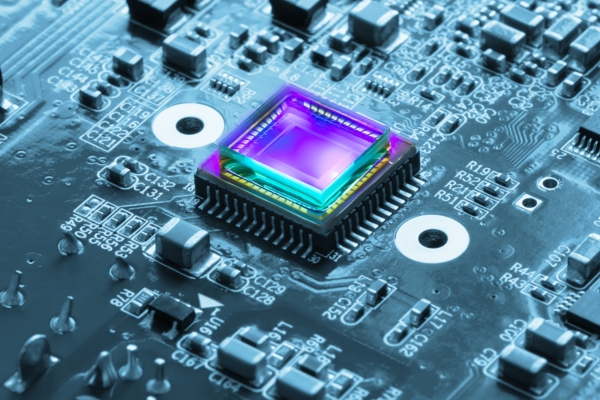

Intelligent Software System

Faroad’s self-developed software supports the editing of non-standard components, path optimization using AI algorithms, and MES integration. This intelligent system streamlines production processes, enhancing quality and efficiency.

Thermal Compensation Calibration

To maintain accuracy, Faroad’s machines feature real-time thermal compensation calibration, adjusting for environmental changes and ensuring consistent component placement.

Real-World Applications and Success Stories

Faroad’s odd shape pick and place machines have made a significant impact across various sectors. For instance, a leading automotive electronics manufacturer integrated the CPM-FB to assemble complex sensor units, achieving a 25% increase in production efficiency. Similarly, a smartphone manufacturer used Faroad’s technology to handle non-standard components, reducing assembly time and improving product quality.

These success stories demonstrate the transformative power of Faroad’s machines in addressing unique manufacturing challenges, highlighting their ability to enhance efficiency, precision, and adaptability.

The Competitive Advantage of Faroad’s Solutions

Faroad’s commitment to innovation and customer satisfaction sets it apart in the market. Here’s why Faroad’s odd shape pick and place machines offer a competitive edge:

Universal Compatibility

Faroad’s machines are compatible with various feeders and components, providing manufacturers with the flexibility to adapt to changing production needs. This universal compatibility is crucial for industries dealing with diverse and complex assemblies.

Cost-Effective Solutions

By offering a single supplier for comprehensive SMT solutions, Faroad reduces the complexity and cost associated with sourcing equipment from multiple vendors. This cost-effectiveness is especially beneficial for manufacturers seeking to optimize their operations.

Robust Global Support

With an extensive sales and after-service network across Southeast Asia, the Middle East, South America, and Europe, Faroad ensures that customers receive the support and assistance they need to succeed.

Conclusion

In the dynamic world of electronics manufacturing, the ability to handle complex, non-standard components with precision and efficiency is key to staying ahead. Faroad’s odd shape pick and place machines provide the perfect solution, designed to meet the unique challenges of modern manufacturing. With advanced features, intelligent integration, and a commitment to quality, Faroad is your partner in achieving manufacturing excellence.

If you’re ready to conquer complex component challenges and gain a competitive edge, explore Faroad’s range of odd shape pick and place machines today or contact our expert team to discuss how we can tailor our solutions to meet your specific needs. Together, let’s innovate the future of electronics manufacturing.