- Introduction

- The Evolving Landscape of SMT Assembly

- Challenges Faced by Modern Manufacturers

- Faroad’s Multifunction Pick and Place Machines: A Comprehensive Overview

- Key Features Enhancing Versatility and Precision

- Real-World Applications and Success Stories

- The Competitive Edge of Faroad’s Solutions

- Conclusion

Introduction

In today’s fast-paced electronics industry, manufacturers are constantly seeking solutions that offer both versatility and precision to meet diverse assembly needs. As product designs become more complex and varied, the demand for adaptable and accurate equipment is paramount. Faroad, a leader in intelligent equipment manufacturing, rises to the challenge with its multifunction pick and place machines. This article delves into how Faroad’s cutting-edge technology is revolutionizing Surface Mount Technology (SMT) assembly across various industries.

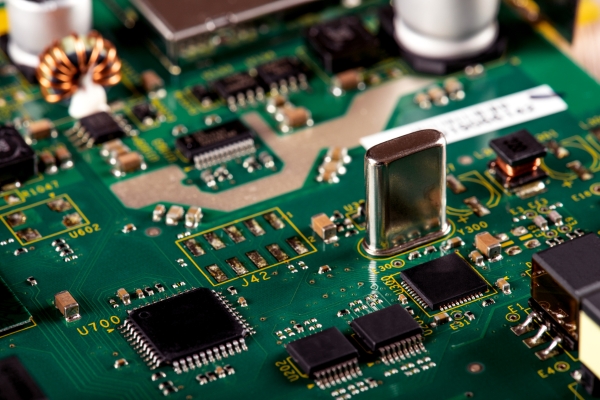

The Evolving Landscape of SMT Assembly

Surface Mount Technology has significantly advanced over the years, transitioning from basic component placement to handling intricate and diverse assemblies. The demand for miniaturized, high-performance devices has led to SMT assembly playing a critical role in manufacturing. As consumer electronics, automotive systems, and IoT devices evolve, manufacturers require machines that can adeptly handle a broad spectrum of components and configurations.

Challenges Faced by Modern Manufacturers

Today’s manufacturers encounter several challenges in SMT assembly:

- Diverse Component Needs: From tiny chips to larger, irregularly shaped components, the variety necessitates machines that can handle different sizes and shapes with ease.

- Flexibility in Production: With frequent changes in product designs, manufacturers need equipment that can quickly adapt without extensive reconfiguration.

- High Precision: As devices become smaller, the margin for error in component placement shrinks, requiring machines that ensure impeccable accuracy.

- Efficiency and Throughput: To meet market demands, manufacturers must maintain high-speed operations without sacrificing quality.

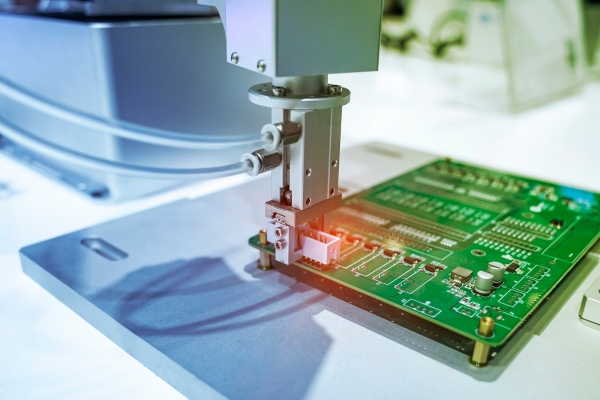

Faroad’s Multifunction Pick and Place Machines: A Comprehensive Overview

Faroad’s multifunction pick and place machines are designed to address these challenges, offering unparalleled versatility and precision. With models like the CPM-F3 and CPM-F5, Faroad delivers solutions that cater to a wide range of SMT assembly needs, from prototype development to full-scale production.

Model Highlights

- CPM-F3: Known for its flexible configuration, this model offers 10 high-speed heads for rapid placement and 4 multi-function heads for handling diverse components, ensuring versatility in production.

- CPM-F5: This machine is optimized for high-efficiency with its integrated placement head and advanced AI path optimization, capable of handling components from tiny chips to larger assemblies with precision.

Key Features Enhancing Versatility and Precision

Faroad’s multifunction pick and place machines are equipped with advanced features that drive their performance:

Flexible Placement Heads

The ability to switch between high-speed and multi-function tasks allows manufacturers to handle a variety of components without the need for constant reconfiguration.

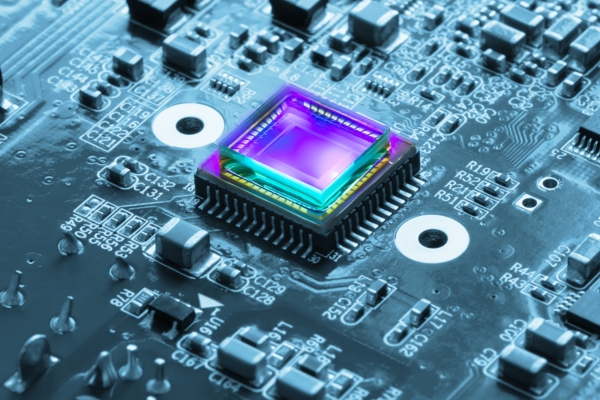

High-Precision Linear Motors

Utilizing linear motors in the XY and Z axes, these machines achieve an accuracy of ±0.035mm, ensuring precise placement even for the smallest components.

Intelligent Software Integration

Faroad’s intelligent software facilitates the editing of non-standard components, path optimization using AI algorithms, and integration with MES systems. This not only enhances production quality but also streamlines operations.

Automatic Calibration and Thermal Compensation

To maintain accuracy and stability, Faroad’s machines feature automatic calibration and thermal compensation, adjusting in real-time to environmental changes and ensuring consistent performance.

Real-World Applications and Success Stories

Faroad’s multifunction pick and place machines have proven their value across various industries. A consumer electronics giant utilized the CPM-F5 to streamline its wearable device assembly, achieving a 30% reduction in production time while maintaining high precision. Similarly, an automotive electronics manufacturer integrated the CPM-F3 into their production line, enhancing their ability to handle diverse assemblies without sacrificing throughput.

These success stories highlight the transformative impact of Faroad’s technology in enhancing efficiency, precision, and adaptability in SMT assembly.

The Competitive Edge of Faroad’s Solutions

Faroad distinguishes itself in the market through a combination of innovative technology, customer-centric design, and strategic market positioning. Here’s why Faroad’s multifunction pick and place machines offer a competitive advantage:

Unified Equipment Management

Faroad’s machines come with a unified equipment management platform, allowing manufacturers to oversee production lines with a single standard. This reduces complexity and enhances operational efficiency, particularly for manufacturers handling varied product lines.

Cost-Effectiveness

Compared to other brands, Faroad provides a cost-effective solution without compromising on quality or performance. This is especially beneficial for manufacturers seeking to optimize their production processes while managing costs effectively.

Global Support and Customization

Faroad offers robust global support through its sales and after-service channels, ensuring customers receive the assistance they need. Moreover, the ability to customize equipment to specific production needs ensures that each solution is tailored for maximum productivity and efficiency.

Conclusion

In the dynamic world of electronics manufacturing, versatility and precision are key to staying ahead. Faroad’s multifunction pick and place machines provide the perfect solution, offering the flexibility and accuracy required to meet diverse SMT assembly needs. With advanced features, intelligent integration, and a commitment to quality, Faroad is your partner in achieving manufacturing excellence.

If you’re ready to enhance your SMT assembly capabilities and gain a competitive edge, explore Faroad’s range of multifunction pick and place machines today or contact our expert team to discuss how we can tailor our solutions to meet your specific needs. Let’s innovate the future of electronics manufacturing together.