High-Precision Multi-Function Pick and Place Machines

Unleash Superior Efficiency and Precision

Advanced Placement Technology

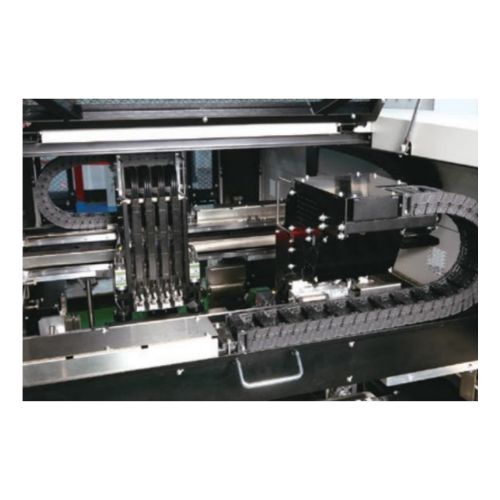

Our multi-function pick and place machines come equipped with flexible placement heads that can be configured to handle both high-speed and multi-functional tasks. The high-precision linear motors in the XY axis and Z axis ensure that components are placed with an accuracy of ±0.035mm, making these machines ideal for intricate and demanding applications.

Intelligent Software Integration

Incorporating a robust MES system, our machines allow for intelligent management of production, quality, and efficiency. This system enables real-time monitoring and calibration, ensuring that your manufacturing processes are always optimized for peak performance. The automatic calibration and thermal compensation devices further enhance the stability and precision of component placement.

Versatile Feeding Solutions

Our machines offer a variety of feeding options, including electric feeders, tube feeders, and automatic IC trays. These systems are designed to handle different material types efficiently, ensuring smooth and continuous production. The integrated light source controller and high-resolution cameras facilitate accurate identification and placement of components, boosting overall production efficiency.

Use Cases and Applications:

- Versatile Electronics Assembly: Ideal for a wide range of electronic products, from consumer electronics to industrial control systems.

- Prototype Development: Perfect for R&D departments that need flexible and adaptable equipment for developing new products.

- Small to Medium Scale Production: Suitable for businesses that require a multifunctional machine for diverse production needs.

- Flexible Manufacturing Systems: Can be integrated into flexible manufacturing systems that produce a variety of products without frequent reconfiguration.

- Wearable Technology: Applicable in the assembly of wearable devices that require the placement of small and diverse components.

Multifunction – Pick And Place Machines

Specs Overview

Model Navigation

Configurations that Define Excellence

Feature Details

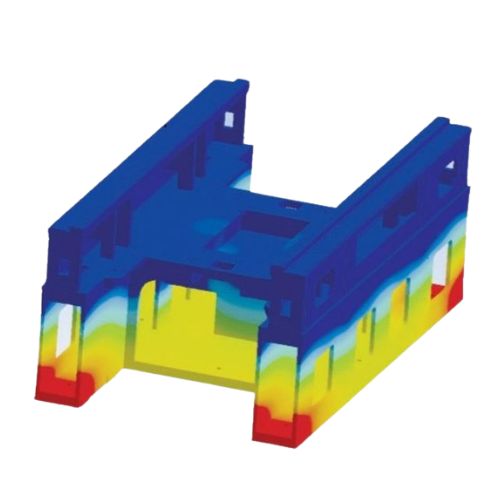

One-piece Cast Frame

A cast one-piece frame undergoes 365 days of natural aging to relieve stress, and adopts a high-temperature annealing process to prevent thermal deformity and thermal deformation of high-speed movement.

High-speed Response And High-Precision Full-closed Loop Control

Y-axis adopts dual linear motor drive to achieve high-speed response, high-precision full closed-loop management.

Dual Gantry Configuration

Single-track and double-track operations are flexibly used through the dual-gantry configuration, and the two sets of placement heads are independently controlled to minimize interference.

Magnetic Levitation Linear Motor And Grating Ruler

Using the advanced linear motor configuration in the industry, the linear motor has longer life span and fully guarantees the stability of the equipment.

Automatic IC Tray (Optional)

Supports up to 20 trays inline with non-stop changing.

Electric Feeder

Support 8/11/21/6 /24/32/ 44/56/72/88mm feeders.

Tube Feeder

Tube feeder has a more stable vibration frequency and can flexibly respond to the feeding needs.

A Variety Of High-end Configurations

Atc Automatic Nozzle Change (Optional)

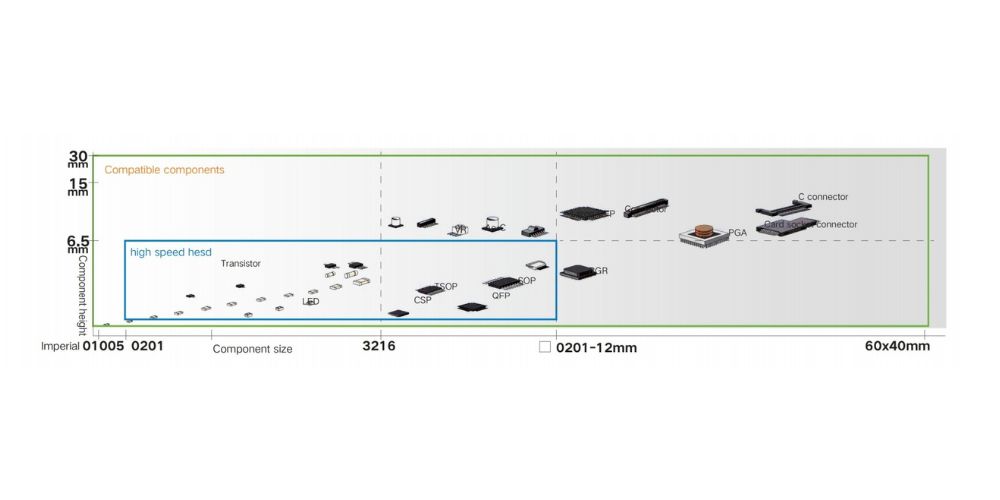

Standard 10 heads can mount 0201 to 1212mm components. Optional 4 heads can mount 01005 to 6040mm components.

Thermal Compensation Calibration

Monitor and automatically correct the placement accuracy in real time to ensure the stability of the equipment.

Pcb Support Plate

Electric support plate adjusts PCB for the upper and lower direction with controllable pressure.

Light Source Controller

Linear scanning camera: high-resolution industrial cameras to achieve higher precision placement. Flying camera: It can identify and correct all CHIP components during the placement process, and the size of the components can be identified within 12*12mm.

Intelligent Software System

Non-standard Components Can Be Edited

Newly developed intelligent digital alignment algorithm used to realize non-standard components/irregular-shaped irregular components by the function of one-click editing.

Path Optimization

To achieve the best equipment utilization rate, the Intelligent algorithms such as ant colony algorithm/cluster analysis/AI deep learning are newly added to realize the optimal optimization path for both picking and placement.

Coordinate Import

One-click import of coordinates data through text files such as text format, EXCEL files, etc.

Support Mes System Collection

MES system can realize intelligent management of equipment production, quality, efficiency, etc. Improve manufacturing efficiency.

Lan Management

Local area network management, software database and online machine database online communication update, realizing local area network network database to prevent virus transmission.

Support Mes Upload

Automatic identification of QR code or bar-code after placement done, then uploads the data to MES server to achieve traceability.

A GUIDE TO

How to choose the perfect pick and place machine for your smt line in 2024?

Explore Models

CPM-F5 – Multi Function Pick And Place Machine

Introducing the CPM-F5, Faroad’s latest high-precision module placement machine, designed to be the pioneer, practitioner, and leader in China’s high-end smart SMT machines. With its cutting-edge technology and versatile configuration, the CPM-F5 delivers unparalleled efficiency and precision, making it the ultimate solution for your SMT production needs.

Functions & Features

High-Efficiency Integrated Placement

The CPM-F5 boasts a high-efficiency integrated placement head, achieving an optimal production capacity of up to 42,000 CPH. It handles a range of components from tiny 0201 chips to large 40mm x 40mm parts, ensuring flexibility and precision. The magnetic levitation motion module guarantees high-speed and stable placement.

Advanced Recognition and Calibration Systems

Equipped with industrial linear cameras and an automatic calibration system with thermal compensation, the CPM-F5 ensures real-time accuracy. The automatic cutting and collecting device for material strips further boosts production efficiency.

Intelligent and Flexible Operations

Supporting MES systems, the CPM-F5 enables intelligent management of production, quality, and efficiency. Features include real-time vacuum detection, automatic material center correction, and advanced path optimization using AI algorithms, ensuring maximum equipment utilization.

Detailed Specification

| Model | Category | CPM-F5 | |

| Mounting head module | Single Arm | Single Arm | |

| Specification | Track module | Monorail | Monorail |

| Number of nozzles | High-speed placement head (10 heads) | Multifunctional placement head (6 heads) | |

| Equipment size | Length x Width x Height | 1380*1880*1550mm | 1380*1880*1550mm |

| weight | weight | About 1850KG | About 1850KG |

| Electrical Specifications | Gas source | 0.5MPa,200L/min | 0.5MPa,200L/min |

| Power supply / Power | AC380/420/480V, 5KW | AC380/420/480V,5KW | |

| Object substrate | PCB size | Monorail: Minimum 50*50mm, Maximum 510*410mm | Monorail: Minimum 50*50mm, Maximum 510*410mm |

| PCB thickness | 0.5-9.0mm | 0.5-9.0mm | |

| PCB fixing method | Pneumatic lifting platform, upper and lower clamps | Pneumatic lifting platform, upper and lower clamps | |

| Optimum placement speed | 42000CPH | 18000CPH | |

| Mounting function | Chip placement accuracy (CPK) | 士 0,035mm(XYZ),CPK ≥ 1.0 | 士 0,03mm(XYZ), CPK ≥ 1.0 |

| Corresponding component range | Flying camera: minimum size: 0201, maximum size: L12*W12*H6.5mm | — | |

| Fixed camera: minimum British 0201, maximum L40*W40*H13mm | Fixed camera: minimum British 0201, maximum L40*W40*H25mm | ||

| MARK Camera field of view | L20mm*w20mm | L20mm*w20mm | |

| Visual system | MARK Camera Type | Area array 500W | Area array 500W |

| Component Camera Type | Flying Camera | — | |

| Fixed Camera | Fixed Camera | ||

| Feeder | Electric feeder | Electric feeder | |

| Number of feeders | Single-side 50-stop (8mm) Double-side 100-stop (8mm, optional) | Single-side 50-stop (8mm) Double-side 100-stop (8mm, optional) | |

| Feeding system | Coil Material Feeder | Tape:8/12/16/24/32/44/56mm | Tape:8/12/16/24/32/44/56/72/88mm |

| Tube material feeder | Number of loads per vibration feeder: | Number of feeding devices per vibration feeder: | |

| 4-20mmx3 tube, 30-40mmx2 tube, 40-50mmX1 tube | 4-20mmx3 tube, 30-40mmx2 tube, 40-50mmX1 tube | ||

| TARY (optional) | TARY cabinet load: L323*W136*H7.5mm, 20 trays | ||

| Optimum placement speed | 42000CPH | 18000CPH | |

| Mounting function | Chip placement accuracy (CPK) | 士 0,035mm(XYZ),CPK ≥ 1.0 | 士 0,03mm(XYZ), CPK ≥ 1.0 |

| Corresponding component range | Flying camera: minimum size: 0201, maximum size: L12*W12*H6.5mm | — | |

| Fixed camera: minimum British 0201, maximum L40*W40*H13mm | Fixed camera: minimum British 0201, maximum L40*W40*H25mm | ||

| RK Camera Field of View | L20mm*w20mm | L20mm*w20mm | |

| Visual system | MARK Camera Type | Area array 500W | Area array 500W |

| Component Camera Type | Flying Camera | — | |

| Fixed Camera | Fixed Camera | ||

| Feeder | Electric feeder | Electric feeder | |

| Number of feeders | Single-side 50-stop (8mm) Double-side 100-stop (8mm, optional) | Single-side 50-stop (8mm) Double-side 100-stop (8mm, optional) | |

| Feeding system | Coil Material Feeder | Tape:8/12/16/24/32/44/56mm | Tape:8/12/16/24/32/44/56/72/88mm |

| Tube material feeder | Number of loads per vibration feeder: | Number of loads per vibration feeder: | |

| 4-20mmx3 tube, 30-40mmx2 tube, 40-50mmX1 tube | 4-20mmx3 tube, 30-40mmx2 tube, 40-50mmX1 tube | ||

| TRAY (optional) | TRAY cabinet load: L323*W136*H7.5mm, 20 trays | ||

| X-axis | High-precision linear motor + grating ruler | High-precision linear motor + grating ruler | |

| Control section | Y-axis | Dual-drive linear motor + grating ruler, full closed-loop control | Dual-drive linear motor + grating ruler, full closed-loop control |

| Z-axis | High precision linear motor | High precision linear motor | |

| R-axis | High precision servo motor | High precision servo motor | |

| MES system connection | MES Collection | Support TCP/IP communication protocol | Support TCP/IP communication protocol |

| MES Upload | Support QR code / barcode recognition / binding upload MES | Support QR code / barcode recognition / binding upload MES |

Get in Touch.

Office

Building 3, Phase II, No. 9 Furong Road, Songgang Street, Baoan District, Shenzhen.

Contact

Open Hours

Monday & Saturday: 9 am — 7 pm

Saturday: 8 am — 12 pm